Wee Heavy. The one style I have brewed 2 other times before and failed at. One was in the middle of a repitched yeast off a used plastic conical that infected nearly 8 batches of beer. That Wee Heavy, even without being an infected gusher, had way too much cherry and no caramel at all. The next one was a semi-descent beer except for the autolysis which made the beer taste like pot roast... but it works great in chili or to braise beef.

I enjoy a good Wee Heavy on a cold Winter night when I want a big, heavy, malty, sweet desert in a glass. It is a very hard style to get right too. Too much bitterness and a lower FG you have more of a Strong Ale. Too little bitterness and a higher FG and it is too sweet. Balancing the mouthfeel, the FG, the bitterness, and the flavor profile is absolutely key. This of course becomes even harder as you go bigger. More alcohol changes the mouthfeel, adds sweetness, but makes it finish a little dryer than the FG can make you think it will. Then toss in the cellaring factor which will inevitably lower the IBUs as isomerized Alpha Acids drop out of solution.

For this iteration I went with a base of Golden Promise, the native base malt to Scotland. It worked great seeing as I got 25# of it for free from a buddy in the brewclub who had half a sack and didn't want it anymore. I mashed only this grain to keep it pure for the second runnings beer so I could get a clearer feel for what that grain brings to the party. I also mashed at 159*F to keep as much residual body as possible for the beer, especially using Oakshire's American Ale which is highly attenuative. I then layered in some malt complexity by steeping the crushed grains in a sack for 30 minutes. I added cara-pils for some body, British Dark Crystal for toffee and burnt sugar, Carastan for another toffee and caramel layer on the lower end, and some Special B for dark fruits and heavy caramel. Top it off with a touch of Black Malt for color and to add a dryness to the finish. I first-wort hopped with Challenger to keep the bitterness in balance, and if any flavor carries through it will still be in style. I went high on Calcium Chloride and low on Gypsum to keep the body and mouthfeel big and rounded. To keep esters and hot alcohols at bay I began fermenting at 60*F and then ramped it up over a few days to 72*F to finish strong, and it did as the krausen was gone in under 2 weeks, kegged in 3. It is now bulk aging in the keg in the garage at ambient temps to drop clear, lager, and round out. It will eventually be bottled with fresh yeast and stored away. It may even get some oak and Scotch.

For this iteration I went with a base of Golden Promise, the native base malt to Scotland. It worked great seeing as I got 25# of it for free from a buddy in the brewclub who had half a sack and didn't want it anymore. I mashed only this grain to keep it pure for the second runnings beer so I could get a clearer feel for what that grain brings to the party. I also mashed at 159*F to keep as much residual body as possible for the beer, especially using Oakshire's American Ale which is highly attenuative. I then layered in some malt complexity by steeping the crushed grains in a sack for 30 minutes. I added cara-pils for some body, British Dark Crystal for toffee and burnt sugar, Carastan for another toffee and caramel layer on the lower end, and some Special B for dark fruits and heavy caramel. Top it off with a touch of Black Malt for color and to add a dryness to the finish. I first-wort hopped with Challenger to keep the bitterness in balance, and if any flavor carries through it will still be in style. I went high on Calcium Chloride and low on Gypsum to keep the body and mouthfeel big and rounded. To keep esters and hot alcohols at bay I began fermenting at 60*F and then ramped it up over a few days to 72*F to finish strong, and it did as the krausen was gone in under 2 weeks, kegged in 3. It is now bulk aging in the keg in the garage at ambient temps to drop clear, lager, and round out. It will eventually be bottled with fresh yeast and stored away. It may even get some oak and Scotch.

Stats:

Gallons: 5.00

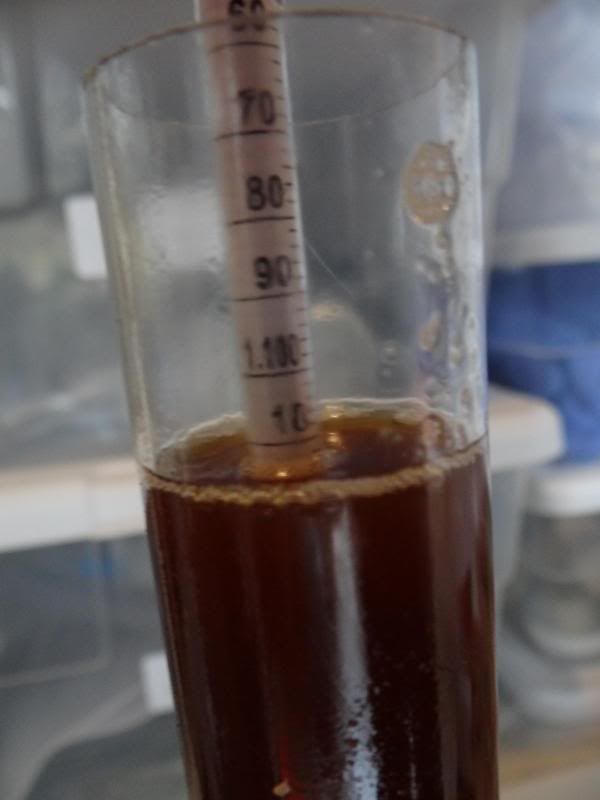

OG: 1.112

FG: 1.033

ABV: 10.4%

IBUs: 28

SRM: 18

Efficiency: 54% (Partigyle)

______________________

Fermentables:

25.00# Golden Promise (86.4%)

Mash 10 hours @ 159*F

Following grains were steeped 30 mins @ 165*F

2.00# MFB Caramel Pilsner (6.9%)

1.00# British Dark Crystal - 75/85L (3.5%)

0.30# Special B Malt (1.0%)

0.14# Black Patent Malt (Crisp) (0.5%)

______________________

Boil: 90 mins

FW 3.00oz US Challenger 7.00%AA

______________________

Kettle Additions:

Gypsum - Mash 4/8 tsp, Boil 1/8 tsp

Calcium Chloride - Mash 1 1/8 tsp, Boil 3/8

Pickling Lime - Mash 3/8 tsp

Yeast Nutrient - 2 taps

Whirfloc - 1 each

______________________

Fermentation:

Cooled to: 52 *F

WY 1056 American Ale (Oakshire Slurry)

60 *F 2 days

64 *F 2 days

68 *F 2 days

72 *F 15 days

______________________

Notes:

1/3-4 Heated 38 quarts to 185 and scooped 3 quarts at a time into the MLT as the pump is not working right again. Hit 159 by 8:45pm. Left bundled in heating blanket and sleeping bag until morning. By 8:30am dropped to 140*F. Ran off first 7 gallons and added steeping grains in a muslin bag. Sparged with 1/2 gallon of last runnings to get all sugars and make up for grain absorbtion. Boiled 90 minutes with hops. Chilled to 52*F. Set to 60*F and aerated for 20 minutes. Pitched over a pint of thick 9 day old Oakshire slurry.

Ramped up by 4 degrees every other day to 72*F then maintained for 2 weeks to finish strong and keep esters low.

1/24 CO2 force racked to purged keg, purged with CO2, and left in garage during cold winter temps to lager, clear, and bulk age, melding the flavors.

1/31/15*** This beer took 2nd Place in Wood Aged Beers at the 2015 KLCC Homebrew Competition***

Ramped up by 4 degrees every other day to 72*F then maintained for 2 weeks to finish strong and keep esters low.

1/24 CO2 force racked to purged keg, purged with CO2, and left in garage during cold winter temps to lager, clear, and bulk age, melding the flavors.

1/31/15*** This beer took 2nd Place in Wood Aged Beers at the 2015 KLCC Homebrew Competition***

No comments:

Post a Comment