Yeast... it is the key factor to fermentation. Without

yeast, there is no beer. Yeast is what turns the sugars in the wort into

CO2, alcohol, fruity esters and spicy phenols (where appropriate), and all the

wonderful flavors we look for in beer. Yeast also can add flavors that we

don't want, off flavors, higher alcohols, and other things that can cause a

beer to no longer be wonderful. The key to making a great beer is healthy

yeast. Yeast, like us, can only do so much work before fatigue sets in

and they have to stop. In order to keep the yeast from quitting before

their work is done they need sufficient nutrients, oxygen, and numbers.

Many hands make for light work. The more yeast you pitch, the

faster they can work, and the less stress exerted on them to finish their job.

There are multiple

ways to get an adequate amount of healthy yeast to pitch. One way is to

buy lots of yeast packs and pitch them all in. Another way is to get a

pitch of yeast from a brewery. The standard way that a homebrewer has

sufficient yeast of the strain they want for the best fermentation is to make a

yeast starter. Basically, you make a small amount of wort 1-2L of 1.040

wort with yeast nutrient, cool it, and pitch the yeast into it. This will

grow the amount of yeast and get them awake and active, ready for fermentation.

You can grow more yeast by adding oxygen as you pitch the yeast. You can grow even more by

shaking the starter whenever you pass it which sends oxygen into the wort while

expelling the CO2 lowering the pressure in the vessel and allowing for more

growth. The best way to make a starter to optimize growth is to place it

on a Stir Plate. A Stir Plate uses magnets to create a constant vortex in

the starter releasing CO2 and infusing with oxygen continually. Commercial

Stir Plates can easily cost $100, even on eBay. But we're homebrewers, we

don't pay absurd prices for beer we can make 5 gallons of for less than 3 6

packs (sometimes less than a bottle), so why would we pay that much for a piece

of equipment that you can make for around $25?

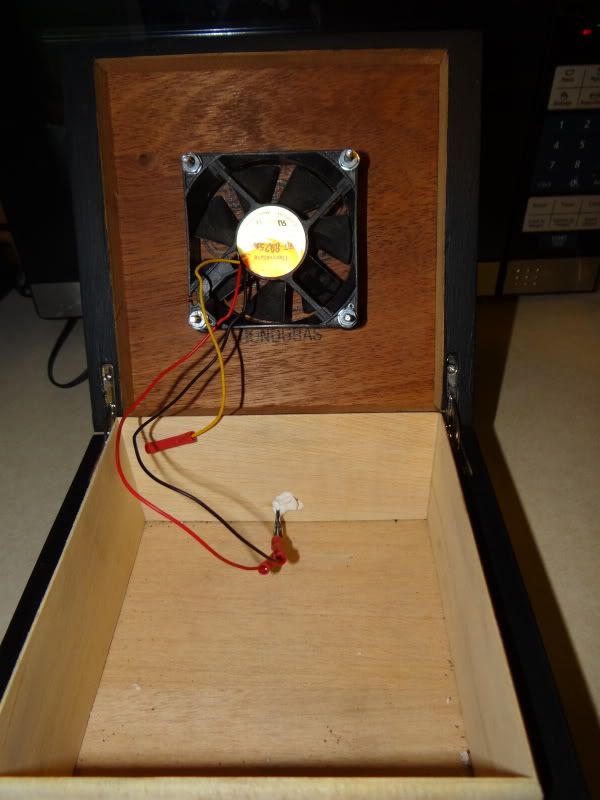

Do you have access

to a hard drive? What about a computer fan? What about a cigar box?

What about an extra 12V power supply (maybe to the old Sega)? Grab

a couple screws, nuts, washers, rubber washers, and some basic tools and you're

good to go. If you want more information on how to build a Stir Plate beyond how I did it, you can always read the article I used to build mine from Brew Your Own.

What you’ll need:

What you’ll need:Wooden cigar box

80mm 12-volt DC fan

12-volt AC/DC wall adapter

Rare earth magnet (from hard drive)

4 - #6-32 x 2” machine screws

4 - #6-32 machine screw nuts

#6 metal washers

4 - 1⁄4” flat neoprene wash

Plastic wire connectors

Tools:

Wire cutters

Drill

13/64 Drillbit

Countersink

Electrical Tape

Electrical Tape

Extra Needed Materials to Use:

2000ml Erlenmeyer flask

Magnetic Stir Bar

Start by opening up the hard drive and removing the rare earth

magnet. Once you have it, place it on

the main hub of the fan and give it a spin to make sure the weight is

distributed. Mark it off with a pen, the

superglue it in place. Next measure the

top of the cigar box to find the center and figure out where to drill your

holes to attach the fan on the inside lid.

Once you have the holes marked out (use an inked q-tip), drill the holes so that they can

sufficiently take the screw. I did a

countersink on mine that will allow not only for the head of the screw to fall

below the level of the lid, but to have room for covering the head of the screws

with wood putty (just sand it down and paint over for a clean look). Open the lid and slide the screws through the

top to the inside. Slide the neoprene washer onto the screw, rubber side towards the box, then a couple washers; next

slide the fan onto the screws, magnet towards the lid. Add a washer to the screw next, then place the machine nut onto the screw and tighten it

until the fan no longer moves (do this on all four screws). If there

is not enough clearance between the lid and fan for it to spin freely, add some

more washers between the neoprene washer and the fan. Once it is set you can

wire it up. Drill a hole through the

back to slide the wire from the 12V power supply through.

Cut the wire of the 12V as close as possible to the part that attached to the device

it was used for (typically the little circular plug). Splice the ends of the fan wires to the 12V

wires using plastic wire connectors and tape on tight. (I just put the ground wire into a plastic wire connector and taped it off). Check to see if you wired it up

correctly and to see if it is stable; it might shake some, place a partially

filled flask on top to see if it stops the rattling. I filled in the hole around the wiring, and

sanded it down as well to make a complete housing. After a paint job it was ready for use.

Once it is ready, make your starter: go here to figure out what size starter to make for your specific batch of beer. Once you know how big your starter needs to be, you take your flask, measure your water, and

dump some of it out into a bowl where you will mix in the DME (1000ml of water to 100g DME makes 1.040 starter wort). Add it back to the flask with some nutrient,

and boil in the flask. Add a couple drops of foam

control to keep it from boiling over and to keep any krausen from blowing off

during growth. Drop in the

magnetic stir bar during the boil to sanitize it. After boiling, cover with foil and chill to

pitching temps (below 80*F) in an ice bath (placing a cooling rack under the flask helps cool quicker). Sanitize

your yeast pack, open, pitch, and recover with the foil. Tilt the flask so that the stir bar is at the

outer edge, and place it on over the center of the plate. You will see the bar magnetize to the magnet

on the fan. Slide it until the flask is

centered. Plug it in, and you will see

the vortex form. Place out of direct

sunlight, and let her roar for a couple days.

You will see it get foggy and creamy.

After it is done, place it in the fridge. On brew day, remove the flask from the

fridge, let it warm up, and when you are ready to pitch - remove the foil, decant most of the wort, swirl up the

yeast, and pitch it in – be careful not to toss the stir bar in with it.

UPDATE: This is an awesome tool to use as you step up your starters, but some times you have a small amount of yeast, like from a bottle or slant/plate, and need to do a 10ml starter, what then. Build a Shaker Tray for the initial steps, then use your Stir Plate for the 100ml and 1000ml steps.

UPDATE: This is an awesome tool to use as you step up your starters, but some times you have a small amount of yeast, like from a bottle or slant/plate, and need to do a 10ml starter, what then. Build a Shaker Tray for the initial steps, then use your Stir Plate for the 100ml and 1000ml steps.

No comments:

Post a Comment